- +91-9322316753, +91-8999468629

- allinoneautomation8@gmail.com

ALL IN ONE AUTOMATION offers round-the-clock and comprehensive port and voyage repairs in all major Ports across the world.

ALL IN ONE AUTOMATIONS mobile repair crews, technicians and engineers are able to continue voyage repairs to any country the vessel sails.

Our port and voyage repairs are fast, cost effective and meet the regulatory requirements. With our equipment and flexible personnel, we perform a wide range of port and voyage repairs. Routine or emergency intervention can include:

We are supplier and Service Provider have been providing complete solution to Marine / Industries as follows:

We are doing the following Electric & Automation Service jobs on board vessels.

1) Central Alarm System, Including Tank levels and Bilge levels.

2) Alarms and Cut outs of Main Engine, Generator, Other E/R Equipment’s & Boilers ETC.

3) Sensors, Transmitters, Indicators Calibration and Repairs.

4) PCL based controllers repair and Conversion, retrofit ETC.

5) Electrical and Electronic inspection, Health check-up and repair support for E/R equipment during Dry docking, Sea trial and Bollard pull trials.

6) PA system fault finding and new Installation.

7) Boiler Automation and Fault finding.

8) IG & IGG System, Automation and fault finding.

9) Tank Gauging System fault finding.

10) ODME, OWS, OMD Automation and fault finding.

11) Incinerator fault finding.

12) Pump Room Automation Service.

13) All Tank Automation and fault finding.

14) All Types Electric and Automation new panel renewal and installation.

15) All Types PCB Repairing and Modification As per Customer Requirement.

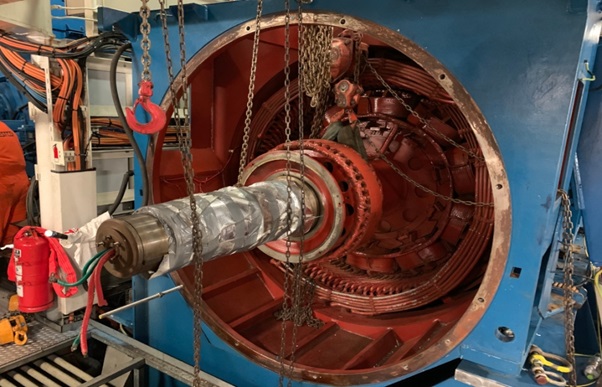

16) Generator overoiling and rewinding.

17) All types Motor& Alternator rewinding/overoiling and as per customer requirement new supply.

18) Auto door system renew as per customer requirement

19) ELCB panel renew as per customer requirement

20) Load cell new system installation and repairing.

21) Generator alarms and cut-out fault finding and retrofitting.

We are doing the following Maintenance jobs on board vessels.

1. Checking the connection of all Electronic cards, Modules, Transmitters and Indicators. Checking Terminals Connections and DC Power Supplies.

2. Cleaning of Electronic Cards, Control system cabinets, Modules, Push buttons, Joysticks, Racks, Transmitters and Indicators.

3. Troubleshooting, Repair, Replacement of defective spares. Calibration and testing.

4. Health Checks of Software based Programmed Control System. Checklist report will be submitted with details of the spare parts and photos.

5. during Sea Trials, Monitoring of Engine Room Equipment, Alarm system, Main Engine safety cut-off. Such as running parameters, temperatures and pressures.

6. All Types Motor Supply, Overhauling and Rewinding.

7. Generator Overhauling and Rewinding.

8. All Types Starter Panels Fault finding and New Installation.

9. Galley Hotplate fault finding and New Installation.

10. Maine Switchboard Maintenance.

11. E/R, ECR, CCR Alarms Fault finding and New Installation.

12. M/E and A/E Safety Cut-outs fault finding and New Installation.

13. All Types Electric / Electronic and Automation Works

14. All types Electric Panels / PLC Base/Electronics Base renewal.

15. All Types PCB Repaired.